Indlela yokukhiqiza kanye nenqubo ye-hot-rolled ribbed steel bar

I-Background technique:

Emakethe yamanje ye-rebar, i-hrb400e ilandisa okwengeziwe.Indlela yokuqinisa i-microalloy iyindlela eyinhloko yokukhiqiza i-hrb400e emhlabeni.I-microalloy ngokuyinhloko i-vanadium alloy noma i-niobium alloy, edla izinsiza eziningi ze-alloy minyaka yonke.Ngenxa yemithombo yamaminerali elinganiselwe equkethe i-vanadium ne-niobium, ukuhlinzekwa kwalezi zakhi ze-alloying kuqinile.Ngakho-ke, uma okuqukethwe kwe-alloy yensimbi ye-hrb400e kungancishiswa, kuzokhiqiza izinzuzo ezinkulu zezomnotho nezenhlalakahle.

Kubuchwepheshe obukhona, ulayini wokukhiqiza ogoqa izintambo ezimbili ngaphandle kokunciphisa kanye nosayizi wokugaya ngokuvamile usebenzisa i-vanadium alloy yokuqiniswa ukuze kukhiqizwe i-hrb400e, kanti amaphesenti amaningi e-vanadium angu-0.035% kuya ku-0.045%.

Ilungelo lobunikazi laseShayina elithi cn104357741a lidalula uhlobo lwekhoyili yensimbi ekwazi ukumelana nokuzamazama komhlaba i-hrb400e kanye nendlela yayo yokukhiqiza.Ngokusebenzisa indlela, umkhiqizo oqediwe ukhiqizwa umshini wokunciphisa nokulinganisa ubukhulu, ongaqinisekisa ukuthi insimbi egoqiwe yokuqedela igoqelwa ekushiseni okuphansi kwe-730 ~ 760 ℃ ukuze kutholwe Ngezinhlamvu ezinhle, le ndlela ayifanele imigqa yokukhiqiza. ngaphandle kokunciphisa izigayo zokulinganisa.Ilungelo lobunikazi laseShayina elingu-cn110184516a lidalula indlela yokulungiselela yesikulufu socingo oluphezulu φ6mm~hrb400e.Ngosizo lomthamo oqinile wokugoqa wemishini, ukushisa okuphansi kokushisa kuqala kusukela ekushiseni okushisa, futhi ukukhiqizwa ngaphandle kwe-microalloying kuyabonakala.Ububi bale ndlela ukuthi Izidingo zamandla nokusebenza kwemoto kwemishini egoqayo nemaphakathi ziphakeme uma kuqhathaniswa, ikakhulukazi ulayini wokukhiqiza we-torsion rolling, okwehlisa impilo yokuhlolwa kwemishini futhi kwenyuse izindleko zokunakekela okokusebenza, namandla esivuno sekhoyili ephezulu φ6mm~hrb400e ekhiqizwa ngale ndlela iyinsalela.Inani elinganele, kunzima ukuqinisekisa izinga lokufaneleka lokusebenza.

Izinto zokusetshenziswa kobuchwepheshe:

Ukusungulwa kwamanje kuhlose ukuhlinzeka ngendlela yokukhiqiza izinsimbi zensimbi ezigoqiwe ezimbambo ezishisayo, ikakhulukazi indlela yokukhiqiza iminenke egoqwe eshisayo yocingo oluphezulu φ8~φ10mm~hrb400e, enqoba ukuntula okubalulwe ngenhla kobuciko bangaphambili futhi inciphise ukukhiqizwa. izindleko.

Isikimu sobuchwepheshe sokusungulwa kwamanje:

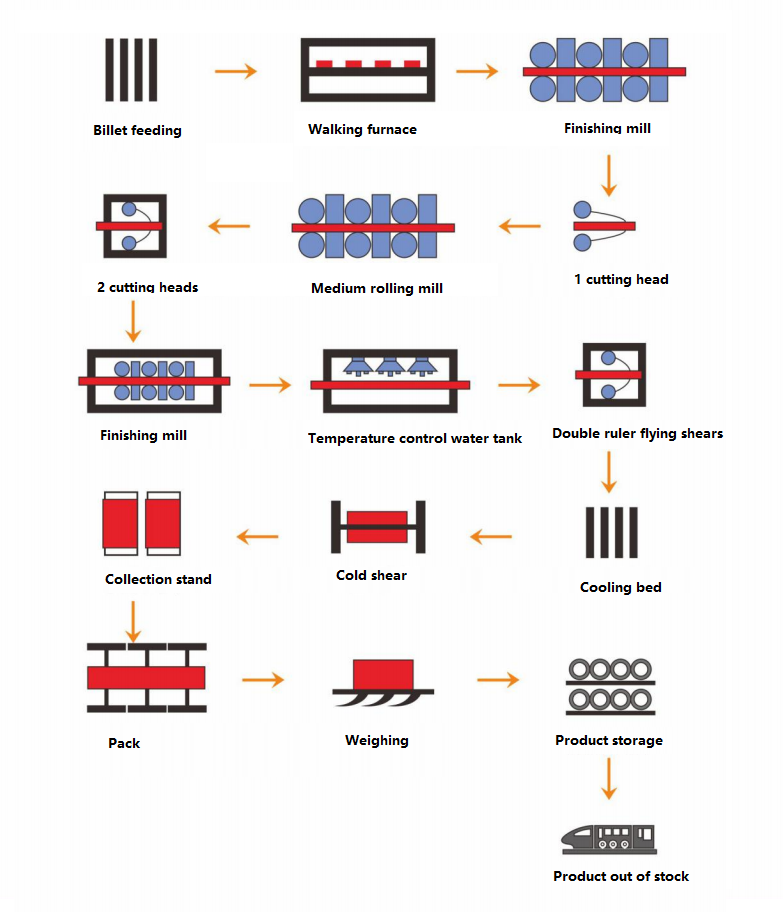

Indlela yokukhiqiza yensimbi egoqwe ngezimbambo ezishisayo, ukucaciswa kwentambo yensimbi eyi-ribbed ngu-φ8~φ10mm, futhi inqubo yezobuchwepheshe ihlanganisa ukufudumeza - i-billeting - rolling rough - rolling medium - cooling - pre-finishing - cooling - finishing - cooling - ukuphotha - Ithebula le-roller elipholile emoyeni-iqoqo lekhoyili-ukupholisa kancane;iphesenti lensimbi yokwakheka kwamakhemikhali ngu-c=0.20%~0.25%, si=0.40%~0.50%, mn=1.40%~1.60%, p≤0.045%, s ≤0.045%, v=0.015%~0.020%, ezinye ziyi-Fe nezici ezingenakugwenywa zokungcola;Izinyathelo ezibalulekile zenqubo zihlanganisa: izinga lokushisa lesithando somlilo ngu-1070 ~ 1130 ℃, izinga lokushisa elingaphambili liyi-970 ~ 1000 ℃, futhi izinga lokushisa lokuqeda liyi-840 ~ 1000 ℃.880℃;izinga lokushisa elibekiwe 845 ~ 875 ℃;izinga lokushisa lokugcina lokugoqa lingaphansi kwezinga lokushisa le-recrystallization ye-austenite zone;ukupholisa okusheshayo nge-fan etafuleni le-roller elipholile emoyeni, ivolumu yomoya ingu-100%;Izinga lokushisa lekhava lingu-640 ~ 660 ℃, izinga lokushisa lesembozo sokugcina ukushisa lingu-600 ~ 620 ℃, futhi isikhathi sesembozo sokugcina ukushisa singu-45~55s.

Umgomo wokusungulwa: ebangeni lokushisa lika-840-880 ℃, izinhlamvu ze-austenite zelulwa ngokushintshashintsha kwe-rolling, kodwa ukubuyiswa kabusha akwenzeki.Kodwa-ke, ama-deformation bands akhiqizwa ezinhlotsheni ze-austenite, futhi iziphetho zama-deformation bands ngokuvamile zisemingceleni yokusanhlamvu, futhi kukhona namabhande okuguqula izinhlamvu njengemingcele ecacile yokusanhlamvu ukuhlukanisa izinhlamvu ze-austenite ezinde.Ngesikhathi senguquko ukusuka ku-austenite ukuya ku-ferrite, yomibili imingcele emide yezinhlamvu ze-austenite kanye nendawo ebonakala sengathi yomngcele wokusanhlamvu isebenza njengendawo ye-nucleation ye-ferrite, okuholela ekucwengisweni kwe-ferrite ngemva kokuguqulwa.Ukuginqika kwezinga lokushisa eliphansi emshinini wokuqedela kunciphisa umthwalo ogoqayo wezigayo ezigoqayo neziphakathi nendawo kanye nezigayo zokuqeda ngaphambi kokuqeda futhi kwandisa impilo yesevisi yemishini.

Imiphumela enenzuzo yokusungulwa yilena elandelayo: ngokungeza inani elincane le-v ukuze kuqiniswe i-microalloy, amandla okukhiqiza ayathuthukiswa, i-v kanye ne-c yakha ama-carbides, adonswa ngesikhathi senqubo yokupholisa ngemva kokugoqa, futhi adlale indima yokuqinisa imvula. .I-hot-rolled wire rod yokusungulwa inamandla aqinile we-600-700mpa, amandla okukhiqiza angu-420-500mpa, amandla okukhiqiza ajwayelekile angaba ngu-450mpa, kanye ne-agt>10%, okuqinisekisa umkhawulo owanele.Amandla esivuno azinzile, futhi izinga lokufaneleka lokusebenza lingaphezu kwama-99%.Okusunguliwe kuyixazulula ngobuchwepheshe inkinga yokuthi i-twist rolling mill inzima ukwenza ukugingqika okunezinga lokushisa eliphansi, inciphisa izindleko ngesisekelo sokuqinisekisa ukuthi umthamo wokukhiqiza awehli, futhi iletha izinzuzo eziphezulu zomnotho.

Izindlela ezinemininingwane

Okuqukethwe kokusunguliwe kwamanje kuphinde kuchazwe ngezansi ngokuhambisana nama-embodiments.

Indlela yokukhiqiza yeqembu lezintambo eziphakeme φ8mm~φ10mmhrb400e iminenke ehlanganisiwe.Inqubo yokugoqa yile: izinga lokushisa eliphumayo: 1080 ~ 1120 ℃, ingena pre-finishing rolling 1030 ~ 1060 ℃, ingena ekuqedeni izinga lokushisa: 850 ~ 870 ℃, izinga lokushisa lokuphotha: 850 ~ 870 ℃, ivolumu yomoya we-fan 100%, ifaka ikhava yokufakelwa izinga lokushisa elingu-640 ~ 660℃, 600 ~ 620℃ ngaphandle kwesembozo sokugcina ukushisa, isikhathi sesembozo sokugcina ukushisa singu-45~55s, futhi ipholisa ngokwemvelo.Ukwakheka kwamakhemikhali kwenduku yocingo yokufanekiselwa kokusungulwa kwamanje kukhonjisiwe kuThebula 1, futhi izici zomshini zenduku yocingo ye-embodiment yokusungulwa kwamanje ziboniswa kuThebula lesi-2.

Ukwakheka kwamakhemikhali (wt%) kwenduku yocingo yesibonelo sethebula

Ithebula 2 Izakhiwo zemishini yesibonelo sezintambo zocingo

Amandla okukhiqiza ocingo oluphakeme φ8mm~φ10mmhrb400e iminenke ehlanganisiwe ekhiqizwa indlela yokusungulwa ikububanzi obungu-420 ~ 500mpa, i-agt ingaphezu kuka-10%, isilinganiso somkhiqizo wamandla singaphezu kuka-1.35, futhi isakhiwo se-metallographic ikakhulukazi i-ferrite kanye ne-pearlite., ukusebenza okuzinzile, amandla esivuno anele kanye nemajini ye-agt, impumelelo yale nqubo ibaluleke kakhulu ekwehliseni izindleko zokukhiqiza kanye nokwandisa inzuzo yemigqa yokukhiqiza egoqayo enemigqa emibili enamathuluzi amadala uma kuqhathaniswa.

Izici zobuchwepheshe:

1. Indlela yokukhiqiza yensimbi egoqwe ngezimbambo ezishisayo, ukucaciswa kwenduku yocingo kungu-φ8mm~φ10mm, futhi inqubo yobuchwepheshe ihlanganisa ukufudumeza - ukukhishwa kwemali - ukugoqa okungalungile - ukugoqa okuphakathi - ukupholisa - ukuqedela - ukupholisa - ukupholisa - ukupholisa - ukuphotha – Ithebula le-cold roller emoyeni—ukuqoqa ikhoyili—ukupholisa okunensayo, okuphawulwe kulokho: iphesenti lensimbi yokwakheka kwamakhemikhali ngu-c=0.20%~0.25%, si=0.40%~0.50%, mn=1.40%~1.60%, p≤ 0.045 %, s≤0.045%, v=0.015%~0.020%, okunye kuyizinto zokungcola ezingagwemeki;Izinyathelo ezibalulekile zenqubo zihlanganisa: izinga lokushisa elithephayo lingu-1070 ~ 1130 ° C, izinga lokushisa langaphambi kokuqeda lingu-970 ~ 1000 ° C, futhi ukugoqa kokuqeda kwenziwa.Izinga lokushisa ngu-840 ~ 880 ℃;izinga lokushisa lokuphotha lingu-845 ~ 875 ℃;izinga lokushisa lokugcina eligoqayo lingaphansi kokushisa kwe-recrystallization ye-austenite zone;ipholiswa ngokushesha yi-fan etafuleni le-roller elipholile emoyeni, futhi ivolumu yomoya ingu-100%;Ithebula le-roller livalwa ngokuvala isembozo sokuvala, izinga lokushisa lokufaka ikhava yokufaka ngu-640 ~ 660 ℃, futhi izinga lokushisa lokuphuma ku-insulation cover lingu-600 ~ 620 ℃, futhi isikhathi sesembozo sokushisa singama-45 ~ 55s.

Isifinyezo sobuchwepheshe

Indlela yokukhiqiza yensimbi egoqwe ngezimbambo ezishisayo, ukucaciswa kwenduku yensimbi eshisayo egoqelwe eshisayo ingu-Φ8mm~Φ10mm, ukwakheka kwamakhemikhali amaphesenti okuqukethwe kwensimbi kungu-C=0.20%~0.25%, Si=0.40%~0.50% , Mn =1.40%~1.60%, P≤0.045%, S≤0.045%, V=0.015%~0.020%, okunye okunye kuyi-Fe nezici ezingagwemeki zokungcola;inqubo yokugoqa iwukuthi: izinga lokushisa lomlilo liyi-1070 ~ 1130 ℃, futhi ukuqedwa kwangaphambili kuyenziwa.Izinga lokushisa eligoqayo lingu-970 ~ 1000℃, izinga lokushisa lokuqeda liyi-840 ~ 880℃;izinga lokushisa lokuphotha lingu-845 ~ 875 ℃;izinga lokushisa lokugcina eligoqayo lingaphansi kokushisa kwe-recrystallization yesifunda se-austenite;%;Ngemuva kokuvala isembozo sokufakwa kwe-roller, izinga lokushisa lokufaka isembozo se-insulation lingu-640 ~ 660 ℃, futhi izinga lokushisa lokuphuma ku-insulation cover lingu-600 ~ 620 ℃, futhi isikhathi sesembozo sokuvala singama-45 ~ 55s.Ngokungeza inani elincane le-V alloy nokuqeda ukugoqa ekushiseni okuphansi, ukusungulwa akuqinisekisi kuphela ukusebenza okuzinzile kwemishini, kodwa futhi kunciphisa okuqukethwe kwe-alloy kanye nezindleko.

Isikhathi sokuthumela: Aug-30-2022