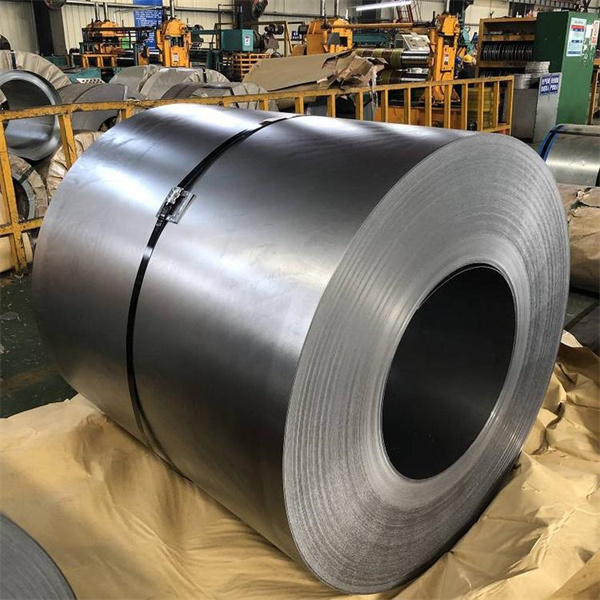

Ubulukhuni be-surfwer bullell yensimbi evulekile yekhabhoni ngokuvamile kungu-55 + -3, futhi ubunzima bensimbi ebandayo ebandayo bunzima obukhombane bungaphezulu kwama-80. Ishidi eligoqiwe elibandayo kanye neshidi elibandayo ngokuvamile linobubanzi obungu-0,1xmm nobubanzi be-100-2000mm; Zombili zenziwe nge-strip evuthayo noma ipuleti lensimbi. .

I-CRS yisifinyezo sensimbi epholile yesiNgisi epholile, okungukuthi, insimbi ebandayo ebandayo. Kubhekisa kwinqubo yokugoqa yensimbi. Isibonelo, i-Q235 ipuleti elejwayelekile le-carbon lensimbi ligingqike, futhi ipuleti lensimbi le-10 # lingaqhamuka. Ubulukhuni baso bungaba sezingeni elihambisanayo ngokuya ngengane yensimbi esetshenzisiwe. .

Yini ibanga leshidi elibandayo elibandayo kune-SPCC? .

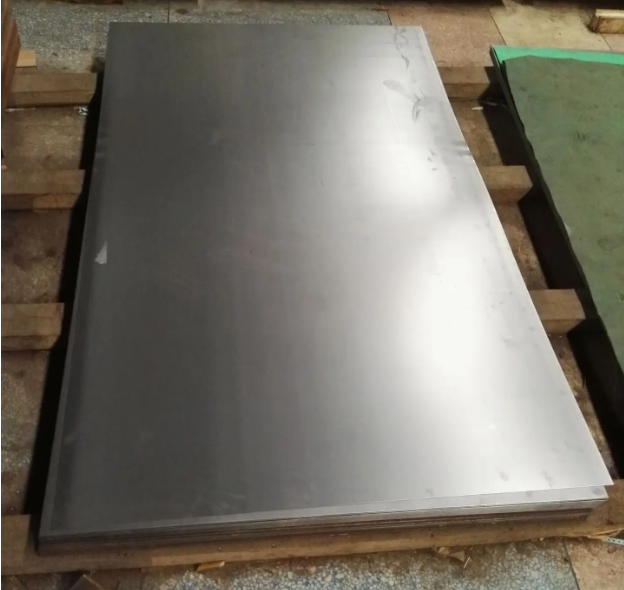

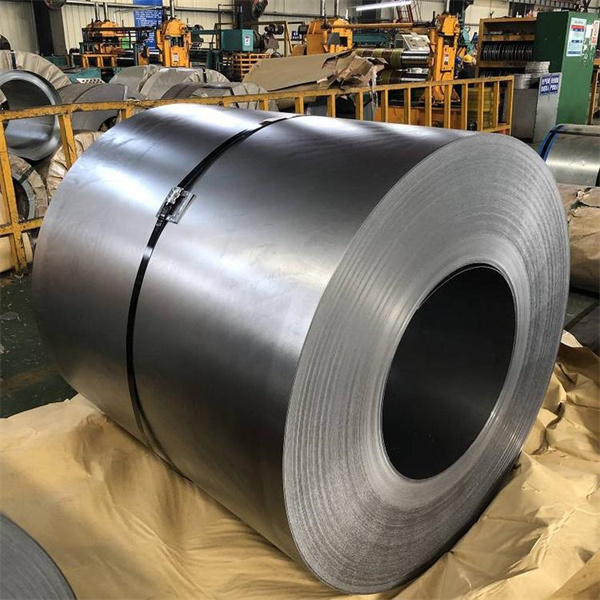

Ishidi elibandayo elibandayo yisifinyezo seshidi elibandayo lensimbi ebandayo ye-carbon elisakhiwe, elaziwa nangokuthi ishidi elibandayo elibandayo, elaziwa ngokuthi ishidi elibandayo, futhi kwesinye isikhathi libhalwe ngephutha njengephepha elibandayo. Ipuleti elibandayo lenziwa ngentambo yensimbi evamile ye-carbon evuthayo yensimbi eshisayo, eqhubeka ibanda ibe yinsimbi enobukhulu obungaphansi kwe-4mm. .

Ishidi elibandayo elibandayo lihlukaniswe: 1/8 kanzima, 1/4 kanzima, 1/2 kanzima futhi egcwele isimo esigcwele. Kunamayunithi amabili aphambili wenani le-Hardness Value: HRB (ama-VV) kanjena: Ikhwalithi ehlukanisa uphawu lwe-HRB (Roclell) HV (amaVickers) 1/8 kanzima. .

Iplateling yepuleti iyipuleti elisongwe elivuthayo elingaphansi kwenqubo efana ne-dephosphorization (ukususwa kokugqwala, izinsalela, njll. Kungabonakala enqubeni yayo yokukhiqiza ukuthi ubulukhuni bawo buyashisa khona ngebanga elifanayo. .

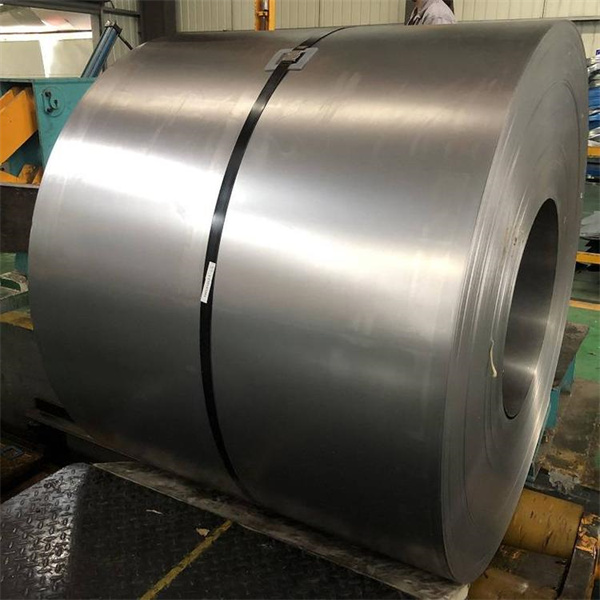

Ngokuyisisekelo akukho mehluko ngobulukhuni bendawo phakathi kokuqhakaza okubandayo nangokugayiwe. Ngoba ingaphezulu le-galvanized ligcwele kuphela ngesendlalelo se-zinc kusuka kuma-microns ambalwa kuya cishe ama-microns angama-20 ku-substrate. Ama-substrates ngokuvamile aqhamuke futhi ashushuluke. Ubulukhuni ikakhulukazi buya ebangeni lokuqukethwe, futhi amamaki ahluka. .

Thatha i-DC01, DC03 njengesibonelo. Umkhawulo ophezulu we-DC01 we-DC0 APRECE FTADE 280 DC03 DC03 umkhawulo ophezulu wamandla we-Revel 240, DC06 + ZE, ahambelana neshidi elibandayo, inani libonisa ibanga lokuxubha, futhi likhulu inani lelo.

Ishidi elibandayo elibandayo lenziwa ngekhoyili eshisayo evuthayo njengento eluhlaza okwesibhakabhaka njengokuqukethwe okuluhlaza, okusongelwe ekushiseni kwegumbi ngaphansi kokushisa kabusha kwamazinga okushisa kabusha, futhi ubulukhuni balo bungama-150hv cishe nge-150hv. Ama-Blade omshini wokugunda ajwayele ukwenziwa ngensimbi yethuluzi, ngobulukhuni be-HRC55 ~ 58 °, ongasika iningi lazo.